ElectroDynamic Fatigue Test Systems

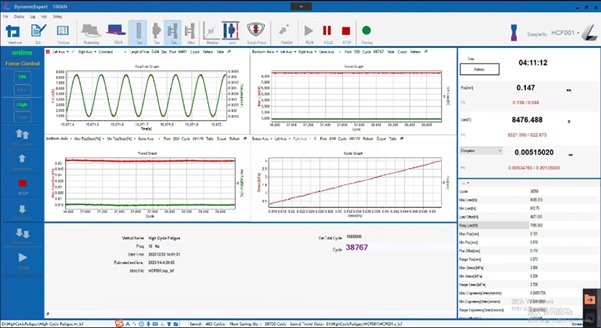

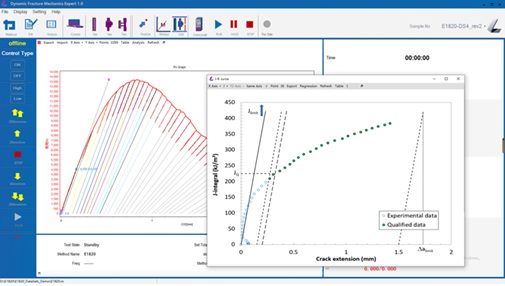

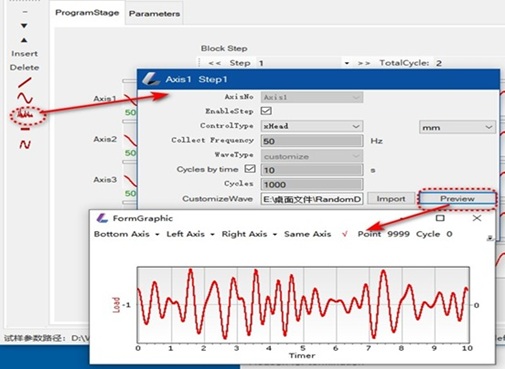

Precision Fatigue Testing for Low-Force, High-Frequency Applications

Testech Solutions Australia supplies advanced electrodynamic fatigue testing systems designed for high-frequency dynamic loading, crack growth analysis, and material durability testing. These systems are ideal for research institutions, aerospace, automotive and materials laboratories requiring precise cyclic loading under tension, compression and bending. We provide nationwide installation, operator training and full NATA-accredited calibration services to ensure compliance with ISO and ASTM fatigue testing standards.

For laboratories that also perform static tensile and compression testing, our Electromechanical Universal Testing Machines offer fully integrated testing solutions with NATA calibration support and compliance with ISO, ASTM and other international standards.