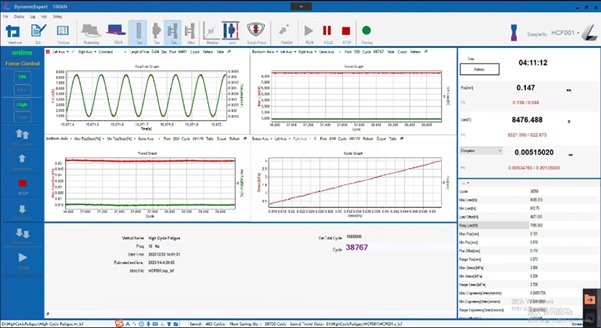

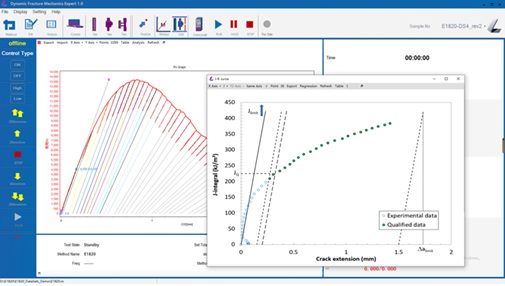

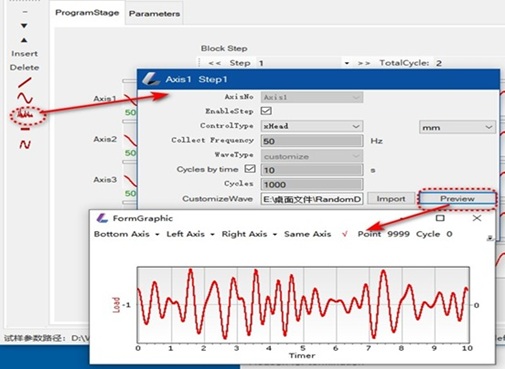

Servo-Hydraulic Dynamic & Fatigue Test Systems

Built upon decades of engineering experience in dynamic testing, our servo-hydraulic fatigue testing systems are designed to deliver comprehensive testing capability, outstanding performance, and long-term reliability. The systems are available in three standard load-frame configurations — table-top, floor-standing (actuator base-mounted), and floor-standing (actuator cross-head-mounted) — with force capacities ranging from 10 kN to 250 kN.

For applications requiring higher loads or special configurations, custom-engineered systems up to 500 kN and 1 000 kN are available. These fatigue test systems are suitable for dynamic and durability studies across metals, composites, construction materials, and new-energy components. Testech Solutions Australia provides nationwide installation, commissioning, and NATA-accredited calibration services to support reliable operation and compliance.