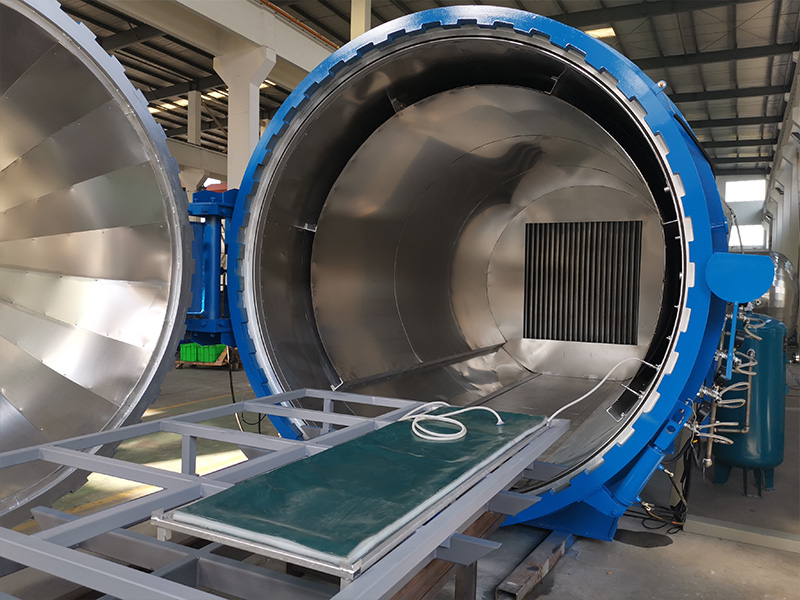

Composite Autoclave

High-Precision Curing for Advanced Composite Structures

Testech Solutions Australia supplies high-performance composite autoclaves designed for curing carbon-fibre, glass-fibre, and advanced composite materials under controlled temperature and pressure. Our autoclave systems are engineered for research laboratories, aerospace, automotive, and industrial manufacturing environments requiring consistent quality and process reproducibility.

Product Overview

These autoclaves provide precise control of temperature, pressure, vacuum, and airflow, ensuring uniform curing and bonding of composite laminates. They are available in various sizes and specifications to suit both laboratory-scale R&D and full-scale production needs. Testech offers installation, commissioning, operator training, and calibration support to ensure safe and compliant operation in Australia.